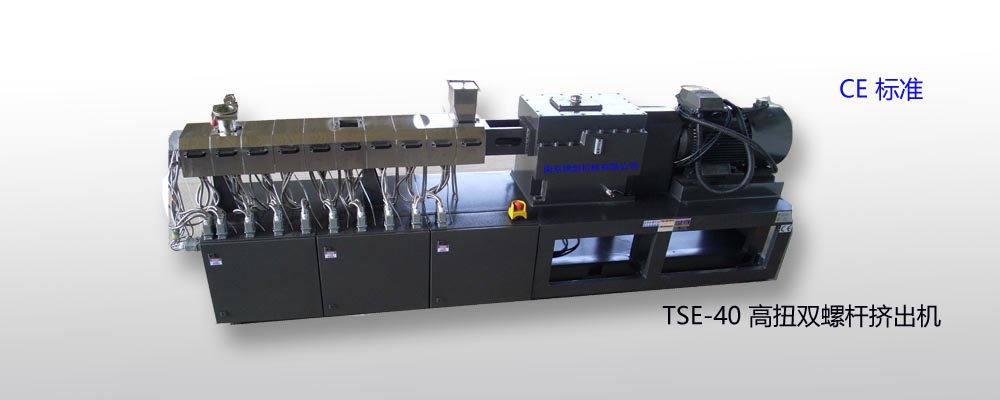

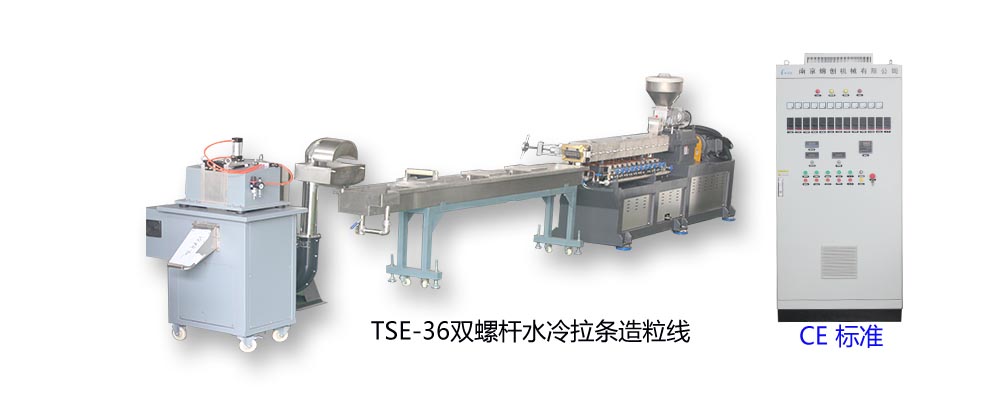

TSE Twin screw extruder

當前位置: 首頁 > 產品展示TSE-36Electret Masterbatch pelletizing line--Special Use Mask meltblown fabric

Capacity:30-50kg/hr

1. Product Description of Polypropylene Meltblown Electret Masterbatch for Masks:

Electret refers to a dielectric material that has the function of storing charges for a long time to release negative ions. The stored charge can be a unipolar true charge (space charge) injected from the outside, or it can be formed by the ordered orientation of dipoles in a polar dielectric Dipole charge, or both types of charge. Increase the ability of the mask to electrostatically adsorb and negative ion sterilization to effectively block droplets, dust, viruses, etc. below the micrometer. This product uses polypropylene as the base material, and the auxiliary agent uses a super-dispersant, so that the auxiliary agent can achieve a micron-level dispersion effect in the masterbatch. The use of this product can increase the density and depth of the charge trapping energy trap in the melt-blown non-woven fabric, effectively release negative ions and store charge to improve the comprehensive filtration efficiency and thermal attenuation resistance of the melt-blown non-woven fabric. In the case of the same fiber fineness and gram weight, it can reduce the resistance of non-woven products and improve the filtration efficiency of non-woven products.

2. Advantages of polypropylene melt-blown electret masterbatch for masks:

1. No need to add new equipment, no need to significantly adjust the existing melt-blown non-woven production process.

2. Does not affect the normal cleaning cycle and service life of the spinneret.

3. Under the condition of the same fiber fineness and the same gram weight, reduce the resistance of non-woven products, and at the same time improve the filtration efficiency and self-sterilization performance of non-woven products. Filtration efficiency ≥95%.